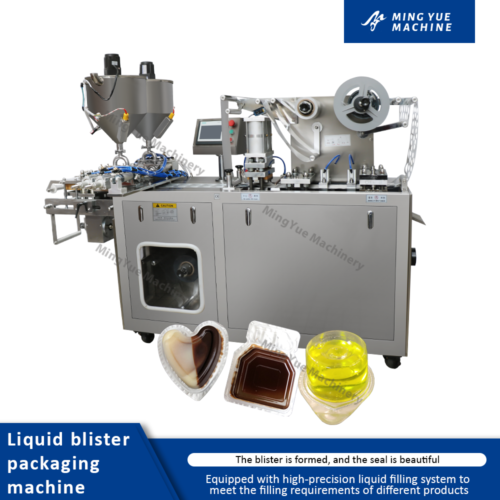

Liquid Bubble Cover Packaging Machine

Liquid Bubble Cover Packaging Machine: Innovative Packaging, Guarding Quality

In the field of modern packaging, liquid bubble wrap packaging machines bring new solutions for the packaging of liquid products with their unique advantages and excellent performance.

1、 Accurate packaging, quality assurance

The liquid blister packaging machine adopts advanced technology, which can accurately package liquid products in the blister. Each bubble cap undergoes strict quality testing to ensure a tight seal and no risk of leakage. This packaging machine can provide reliable protection for liquid products such as drugs, cosmetics, and food, maintaining the freshness, stability, and safety of the products.

2、 Efficient production, improving efficiency

Capable of high-speed packaging, able to complete a large number of liquid product packaging tasks in a short period of time. Its automated operation process greatly reduces manual intervention and lowers labor costs. Meanwhile, stable performance ensures continuous production, improving production efficiency for enterprises and meeting high market demand.

3、 Innovative design, adaptable to a wide range

The design of the liquid blister packaging machine is unique and adaptable to the packaging needs of different types and specifications of liquid products. Suitable packaging solutions can be found for both low-dose oral liquids and high-dose liquid cleaning agents. In addition, customized design can be carried out according to customers’ special requirements to meet personalized packaging needs.

4、 Intelligent control, easy to operate

Equipped with an intelligent control system, the operating interface is simple and intuitive. The operator only needs to easily set the parameters, and the packaging machine can automatically complete the packaging process. At the same time, it also has fault self diagnosis and alarm functions, which facilitate timely troubleshooting and ensure the normal operation of the equipment.

5、 Safe and reliable, use with confidence

Pay attention to safety performance and adopt multiple safety protection measures, such as overload protection, emergency stop, etc., to ensure the safety and reliability of the equipment during operation. At the same time, a strict quality control system ensures that every liquid blister packaging machine meets high standard quality requirements.

6、 Environmental protection, energy conservation, and sustainable development

Fully consider environmental and energy-saving factors in the design and manufacturing process. Using environmentally friendly materials to reduce pollution to the environment. At the same time, optimizing the energy consumption of equipment, reducing operating costs, and contributing to the sustainable development of enterprises.

In short, the liquid bubble wrap packaging machine has become an ideal choice for liquid product packaging due to its precise packaging, efficient production, innovative design, intelligent control, safety and reliability, and environmental protection and energy saving characteristics. Let’s use this advanced packaging equipment together to create perfect packaging for liquid products, enhance brand value, and create a better future together.